SECTOR: 50% CLEAN ECONOMY / 50% ADVANCED MANUFACTURING

Breakthrough Victoria is investing $2.5 million in Victorian company Xefco to reduce water pollution in the global textile industry.

Breakthrough Victoria’s investment in Xefco supports home grown research and will help the company scale and expand its manufacturing capability. The investment is another example of BV helping to commercialise new technologies, enabling Xefco to continue growing and expanding while remaining in their home state.

THE INVESTMENT

Type: Venture |

Stage: Series A |

Investment vehicle: Preference shares |

BV investment: $2,500,000 |

WHO ARE XEFCO?

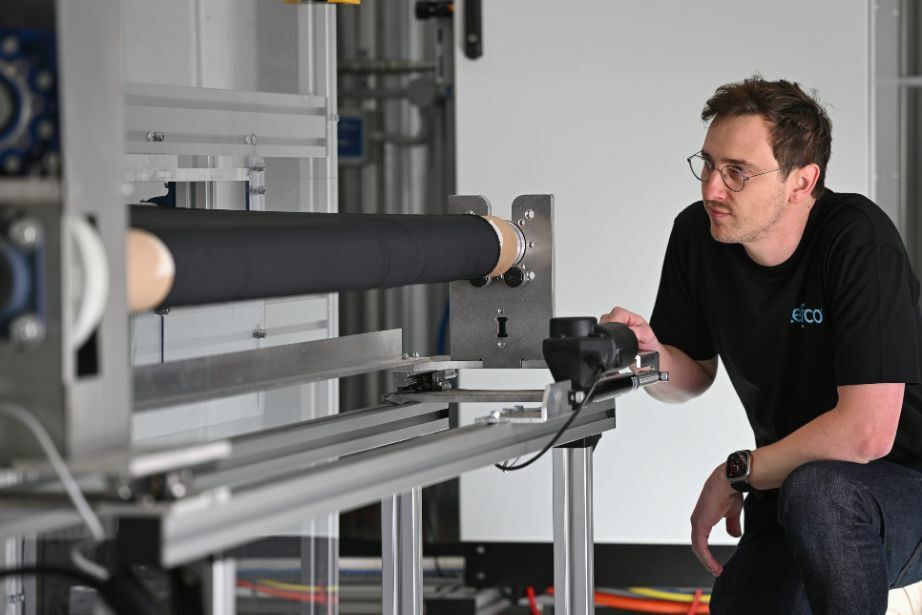

Xefco was founded by Brian Conolly and Tom Hussey back in 2018. They developed Ausora, a proprietary water-free dyeing and finishing technology, allowing for dyeing and finishing of textiles to be completed without the use of water.

The sustainable textile technology company currently employs 18 staff. They’ve established a R&D facility and pilot manufacturing plant in Geelong and are in trials with a number of notable commercial partners.

THE PROBLEM

The US$2 trillion textile market produces about 600 billion metres of fabric annually. However, it is also considered one of the most polluting industries in the world, responsible for significant water pollution, industrial waste and emissions.

An eco-conscious preference for more sustainable fashion has been growing among consumers in recent years. Consumers have become increasingly aware of the negative environmental impact of the current textiles production system, including the harm caused by toxic chemicals in the dyeing the finishing process.

THE SOLUTION

Xefco’s Ausora technology can deliver significant environmental outcomes more efficiently than traditional methods. The unique capabilities of Ausora’s plasma enhanced chemical vapour deposition (PECVD) coating technology significantly reduces the complexity of the chemistry involved and opens up avenues for the use of biobased and sustainably sourced chemicals.

Since the technology doesn’t require any water, it enables the dyeing and finishing process to be located closer to production, and at a major cost benefit to the dyeing mill and garment manufacturer because of the lower inputs required. It also requires 86% less energy compared to traditional fabric dyeing and finishing methods, potentially reducing global carbon emissions.

As a result, Xefco’s solution eliminates toxic dyeing and finishing chemistry from the textile supply chains, reducing exposure of toxic materials to their workers and their communities.

The textile dyeing and functional finishing markets are significant opportunities for Xefco, with major brands looking for alternatives that are both environmentally friendly and more aligned with customer expectations.

BENEFIT TO VICTORIA

Breakthrough Victoria’s investment in Xefco will create new jobs as the company grows.

Xefco’s technology will be a significant contributor to achieving the Federal government’s goal of achieving 26-28% reduction of greenhouse gases emissions by 2030.

Other benefits include:

Victorian jobs

- Xefco plans to create new jobs in Victoria and Australia.

Victorian manufacturing

- The company plans to engage a large contract manufacturer as the business scales and new machines need to be built and deployed.

R&D collaboration

- Xefco has strong research ties with Victoria-based Deakin University.

- It collaborates closely with the Institute for Frontier Materials (Deakin IFM) and has an R&D and pilot manufacturing facility at Deakin Manufactures complex.

- Xefco is also a founding industry partner of Deakin University’s Recycling and Renewable Energy Commercialisation Hub (REAHC) and the ARC Research hub for Future Fibres.

Consumer

- Xefco’s technology enables end consumers to make more climate-friendly choices.

- Reduction of individual carbon footprints on a national scale through sustainable fashion choices, compounding to more significant contributions on a global scale.